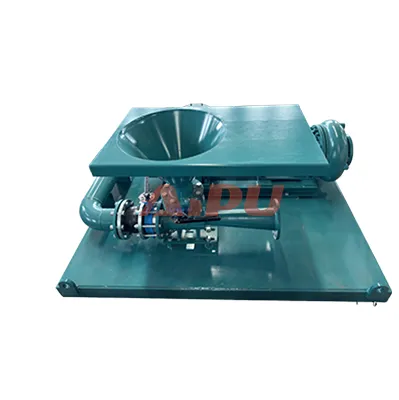

JET MIXING DEVICE

Professional high-velocity mixing system for drilling fluids. Achieves 95%+ additive homogenization, reduces mixing time by 80%, API 13C compliant.

info@aipusolidcontrol.comProduct Showcase

Discover the advanced features and specifications of our high-performance jet mixing device

Key Features

The AIPU Jet Mixing Device utilizes high-velocity fluid dynamics (up to 35m/s nozzle velocity) for precision drilling fluid conditioning. Compatible with API 13C compliant solids control systems, achieving 95%+ additive homogenization.

High Efficiency

Achieves 95%+ additive homogenization with up to 35m/s nozzle velocity for superior mixing quality.

Time Saving

Reduces mixing time by 80% compared to conventional mixing methods.

Durable Design

Features dual mechanical seal system (IP69K) and Waukesha bearing assemblies for long life.

API Compliant

Compatible with API 13C compliant solids control systems and ANSI B73.1 standards.

Technical Specifications

Detailed specifications for the AIPU Jet Mixing Device series

| Model | Sand Pump | Power (kW) | Capacity (m³/h) | Head (m) | Nozzle (mm) |

|---|---|---|---|---|---|

| APSLH110-20 | APSB3×2 | 11 | 50 | 25 | 20 |

| APSLH150-20 | APSB4×3 | 15 | 80 | 21 | 20 |

| APSLH185-25 | APSB5×4 | 18.5 | 100 | 21 | 25 |

| APSLH220-25 | APSB5×4 | 22 | 105 | 27 | 25 |

| APSLH300-35 | APSB5×4 | 30 | 110 | 32 | 35 |

| APSLH370-35 | APSB6×5 | 37 | 190 | 24 | 35 |

| APSLH450-40 | APSB6×5 | 45 | 220 | 23 | 40 |

| APSLH550-50 | APSB8×6 | 55 | 250 | 24 | 50 |

| APSLH750-50 | APSB8×6 | 75 | 255 | 32 | 50 |

Technical Advantages

Mechanical Design

- Dual mechanical seal system (IP69K)

- Waukesha bearing assemblies

- Zero backflow venturi design

- High-velocity nozzle up to 35m/s

Process Features

- 1:1.8 mixing ratio efficiency

- ANSI B73.1 compliant

- 3-stage venturi hydration process

- API 13C system compatibility

Jet Mixing Device Detailed Overview

The SLH series jet mixing system utilizes high-velocity fluid dynamics for precision drilling fluid conditioning. Compatible with API 13C compliant solids control systems, achieving 95%+ additive homogenization.

Primary Application: Designed for mud weighting and conditioning across various drilling environments, including onshore and offshore operations. Capable of 50-255m³/h barite mixing capacity.

Applications & Performance

As a specialized mixing equipment in drilling fluid systems, it is widely used in:

- Mud weighting with barite and other additives

- Polymer activation and hydration processes

- Drilling fluid conditioning and homogenization

- Chemical additive mixing systems

- Mud plant and solids control operations

Performance Benefits:

- 50-255m³/h barite mixing capacity

- 3-stage venturi hydration process for polymer activation

- 80% reduction in mixing time compared to conventional methods

- 95%+ additive homogenization efficiency

AIPU Jet Mixing Device Technical Features

- High-velocity fluid dynamics with up to 35m/s nozzle velocity

- Zero backflow venturi design for efficient mixing

- Dual mechanical seal system (IP69K rated) for reliability

- Waukesha bearing assemblies for smooth operation

- 1:1.8 mixing ratio efficiency for optimal performance

- Compact design for easy integration into existing systems

- ANSI B73.1 compliant construction

- API 13C system compatibility for standardized operations

- Easy maintenance with accessible service points

Customization Options

Tailored for global markets, AIPU offers flexible configurations:

- Power options: Multi-voltage compatibility (380V-690V/50-60Hz)

- Certifications: ATEX/IECEX/UL/CSA available

- Material options: Carbon steel/UNS S31803 duplex stainless steel

- Nozzle sizes: Various sizes from 20mm to 50mm

- Capacity ranges: 50-255m³/h models available

- Surface finishing: Custom coating colors per customer specifications

The AIPU Jet Mixing Device is engineered to deliver consistent performance in demanding drilling environments. Our mixing devices are designed with operator safety and ease of maintenance in mind, featuring quick-access panels and simplified maintenance procedures.

Application Scenarios

Versatile applications across various drilling and mixing operations

Mud Weighting

Specifically designed for barite and weighting material mixing with 50-255m³/h capacity.

Polymer Activation

3-stage venturi hydration process for efficient polymer activation in drilling fluids.

Drilling Fluid Conditioning

Efficient conditioning and homogenization of drilling fluids for optimal performance.

Chemical Additive Mixing

Perfect for mixing various chemical additives into drilling fluids with high efficiency.

Mud Plant Operations

Essential equipment in mud plants for consistent fluid preparation and quality control.

Solids Control Systems

Integrated into solids control systems for efficient fluid mixing and conditioning.

Why Choose AIPU Jet Mixing Device

Industry-leading benefits for your drilling fluid operations

Superior Mixing Efficiency

Achieves 95%+ additive homogenization with high-velocity fluid dynamics for consistent mixing quality.

Significant Time Savings

Reduces mixing time by 80% compared to conventional methods, improving operational efficiency.

High Capacity Range

Available in 50-255m³/h capacities to suit various drilling operations and requirements.

Robust Construction

Built with dual mechanical seals (IP69K) and Waukesha bearings for reliable, long-lasting performance.

Industry Compliant

Compatible with API 13C systems and ANSI B73.1 standards for seamless integration.

Flexible Customization

Available in various configurations with multiple material options and certification requirements.

Customer Testimonials

What our clients say about AIPU Jet Mixing Devices

The AIPU Jet Mixing Device has transformed our mud weighting operations. The 80% reduction in mixing time has significantly improved our overall drilling efficiency and reduced downtime.

We've been using the AIPU Jet Mixer for over two years in our offshore operations. The reliability and efficiency of this equipment have been outstanding, with minimal maintenance required.

The homogenization efficiency of the AIPU Jet Mixing Device is exceptional. We consistently achieve over 95% additive mixing, which has improved our drilling fluid performance significantly.

Need Professional Jet Mixing Solutions?

Contact our experts for customized equipment and system recommendations tailored to your drilling fluid requirements