MUD CENTRIFUGE

High-performance horizontal decanter centrifuge for efficient solid-liquid separation in drilling operations. Removes 2-7μm particles with up to 2035G force, ensuring optimal drilling fluid properties and barite recovery.

info@aipusolidcontrol.comProduct Showcase

Discover the advanced features and specifications of our high-performance mud centrifuges

Key Features

The AIPU Mud Centrifuge is a horizontal decanter centrifuge designed as the final stage in solids control systems, effectively removing 2-7μm particles from drilling fluids. With configurations ranging from 500-2100G force, it provides precise control over drilling fluid properties and optimal barite recovery.

High G-Force Separation

Up to 2035G force for efficient separation of 2-7μm particles from drilling fluids.

Barite Recovery System

Low-speed configuration (500-700G) for optimal barite recovery and cost savings.

Premium Construction

SS304/316 construction with hard-faced scroll components and precision balancing.

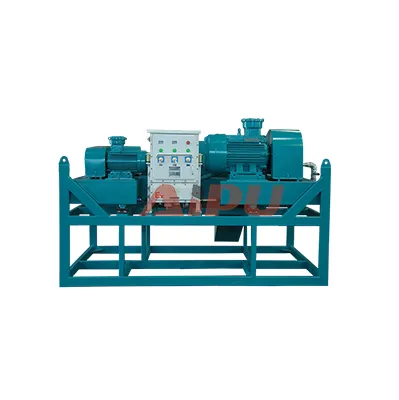

Dual-Motor Configuration

Separate main and back drive motors for precise speed control and reliability.

Technical Specifications

Detailed specifications for the AIPU APLW Series Mud Centrifuges

| Model | APLW450×842-N | APLW450×1000-N | APLW600×1019-N | APLW355×1257-N | APLW450×1258-N | APLW530×1320-N |

|---|---|---|---|---|---|---|

| Bowl Diameter | Φ450mm | Φ450mm | Φ600mm | Φ355mm | Φ450mm | Φ530mm |

| Bowl Length | 842mm | 1000mm | 1019mm | 1257mm | 1258mm | 1320mm |

| Speed | 1800rpm | 2200rpm | 1500rpm | 3200rpm | 3000rpm | 2200rpm |

| Main Drive | 22kW | 37kW | 55kW | 30kW | 37kW | 55kW |

| Back Drive | 5.5kW | 7.5kW | 22kW | 7.5kW | 11kW | 22kW |

| Capacity | 40m³/h | 50m³/h | 60m³/h | 35m³/h | 60m³/h | 65m³/h |

| Cut Point | 5-7μm | 5-7μm | 5-7μm | 2-5μm | 2-5μm | 2-5μm |

| G-Force | 815G | 1215G | 705G | 2035G | 2250G | 1817G |

| Feed Pump | 4kW | 5.5kW | 11kW | 7.5kW | 7.5kW | 7.5kW |

Centrifuge Configurations

Low-Speed Barite Recovery

500-700G force, 1600-1800rpm operation specifically designed for optimal barite recovery in weighted mud systems, minimizing valuable weight material loss.

Medium-Speed Viscosity Control

800G force, 1800-2200rpm operation for effective viscosity control by removing colloidal particles in various drilling fluid systems.

High-Speed Ultra-Fine Separation

1200-2100G force, 2200-3000+rpm operation for removing ultra-fine particles (2-5μm) in demanding drilling applications.

Customization Options

Drilling Fluid Centrifuge Detailed Overview

The drilling fluid centrifuge, typically a horizontal decanter centrifuge, serves as the final stage in solids control systems, removing 2-7μm particles from drilling fluids. It is essential for maintaining optimal drilling fluid properties, controlling viscosity, and recovering valuable barite in weighted mud systems.

Primary Application: As the final stage in solids control systems, mud centrifuges are critical for both non-weighted and weighted mud systems. In non-weighted systems, they remove solids >2μm missed by desanders and desilters. In weighted systems, they control viscosity by eliminating colloidal particles while maximizing barite recovery.

Applications & Performance

The AIPU Mud Centrifuge provides essential solid-liquid separation capabilities in various drilling applications:

- Non-Weighted Mud Systems: Removes solids >2μm that are missed by desanders and desilters, ensuring clean drilling fluid circulation

- Weighted Mud Systems: Controls viscosity by eliminating colloidal particles while maximizing valuable barite recovery

- Barite Recovery: Low-speed configurations (500-700G, 1600-1800rpm) specifically designed for optimal barite recovery

- Viscosity Control: Medium-speed configurations (800G, 1800-2200rpm) for effective viscosity management

- Ultra-Fine Separation: High-speed configurations (1200-2100G, 2200-3000+rpm) for removing 2-5μm particles in demanding applications

- Environmental Compliance: Reduces waste volume and enables drilling fluid recycling for environmental compliance

Three Centrifugal Configurations

Low-Speed Centrifuge

500-700G Force | 1600-1800 RPM

Specifically designed for barite recovery in weighted mud systems. This configuration maximizes the recovery of valuable weight material while effectively separating undesirable solids, significantly reducing operational costs associated with barite replacement.

Medium-Speed Centrifuge

800G Force | 1800-2200 RPM

Optimized for viscosity control by removing colloidal particles from drilling fluids. This configuration maintains optimal fluid properties for efficient drilling operations while extending the usable life of drilling fluids.

High-Speed Centrifuge

1200-2100G Force | 2200-3000+ RPM

Engineered for ultra-fine separation in demanding drilling applications. Removes particles as small as 2-5μm, ensuring the highest quality drilling fluid for precision drilling operations and extended equipment life.

AIPU Mud Centrifuge Technical Advantages

- Premium Construction: SS304/316 stainless steel construction with hard-faced scroll components for extended service life

- Precision Engineering: Dynamic balancing to ISO standards ensures smooth operation and minimal vibration

- Dual-Motor Design: Separate main and back drive motors provide precise speed control and differential adjustment

- Modular Maintenance: Designed for easy access to all components, reducing maintenance time and costs

- Premium Components: SKF/FAG bearing systems and high-quality mechanical seals ensure reliable operation

- Flexible Configurations: Multiple models available with capacities from 35-65m³/h and cut points from 2-7μm

- High G-Force Capability: Up to 2250G force for superior separation efficiency

- Corrosion Resistance: Suitable for both water-based and oil-based drilling fluids

- Safety Features: Comprehensive safety systems including overload protection and emergency stops

How It Works

The horizontal decanter centrifuge operates on the principle of sedimentation under centrifugal force. Drilling fluid enters the rotating bowl through a stationary feed tube. Under high centrifugal force (500-2250G), solids are forced to the bowl wall while clarified liquid moves toward the center. A helical conveyor (scroll) rotating at a slightly different speed continuously moves separated solids toward the discharge ports, while clarified liquid exits through adjustable weirs.

Customization Options

Tailored for global markets and specific operational requirements, AIPU offers comprehensive customization:

- Material Selection: SS304, SS316, or specialized alloys based on fluid chemistry and operating conditions

- Electrical Systems: Custom voltage/frequency adaptations, control systems, and safety features

- Certification Packages: ATEX, IEC, UL, DGMS certifications for different regional requirements

- Performance Optimization: Custom bowl designs, scroll configurations, and differential speed controls

- Integration Features: Skid-mounted systems, integrated feed pumps, and automation packages

- Aesthetic Customization: RAL color matching and custom branding options

- Monitoring Systems: Advanced sensors, remote monitoring, and data logging capabilities

The AIPU Mud Centrifuge is engineered to provide reliable, efficient solid-liquid separation in the most demanding drilling environments. Its robust construction, flexible configurations, and precision engineering make it an essential component of any modern solids control system, delivering significant cost savings through improved drilling fluid management and barite recovery.

Application Scenarios

Versatile applications for efficient solid-liquid separation in drilling operations

Barite Recovery Systems

Low-speed centrifuges specifically designed for optimal recovery of valuable barite in weighted drilling fluids, significantly reducing material costs.

Viscosity Control

Medium-speed configurations for removing colloidal particles that affect drilling fluid viscosity, maintaining optimal fluid properties.

Ultra-Fine Solids Removal

High-speed centrifuges for removing 2-5μm particles that can damage equipment and reduce drilling efficiency.

Drilling Fluid Recycling

Enables efficient recycling of drilling fluids by removing fine solids, reducing waste volume and environmental impact.

Directional Drilling

Essential for maintaining clean drilling fluids in directional drilling operations where fluid properties are critical.

Offshore Operations

Compact, efficient designs suitable for space-constrained offshore platforms where drilling fluid management is critical.

Why Choose AIPU Mud Centrifuge

Industry-leading benefits for efficient solid-liquid separation

Significant Cost Savings

Barite recovery capabilities can reduce weight material costs by up to 40%, while efficient solids removal extends drilling fluid life.

Enhanced Drilling Performance

Clean drilling fluids improve rate of penetration, reduce torque and drag, and minimize equipment wear for more efficient drilling.

Flexible Configurations

Multiple speed options (500-2250G) and capacity ranges (35-65m³/h) to match specific drilling requirements and fluid types.

Premium Construction Quality

SS304/316 construction, hard-faced components, and precision balancing ensure reliable operation in harsh drilling environments.

Reduced Environmental Impact

Efficient solids removal reduces waste volume and enables drilling fluid recycling, minimizing environmental footprint.

Easy Maintenance & Service

Modular design with accessible components reduces maintenance time and costs, while global support ensures optimal performance.

Customer Testimonials

What our clients say about AIPU Mud Centrifuges

We've been using the AIPU APLW450×1258-N centrifuge in our Gulf of Mexico operations for over three years. The barite recovery has been exceptional, saving us approximately $150,000 per well in weight material costs. The high G-force capability effectively handles our demanding drilling conditions.

Our operations in the Middle East require equipment that can handle high temperatures and harsh conditions. The AIPU centrifuges have performed reliably with minimal maintenance. The stainless steel construction has held up well against corrosion, and the barite recovery has significantly reduced our operational costs.

We installed AIPU centrifuges across our African operations to improve our solids control efficiency. The results have been impressive - cleaner drilling fluids, reduced equipment wear, and significant savings on barite. The modular design makes maintenance straightforward, and local technical support has been responsive.

Need Professional Mud Centrifuge Solutions?

Contact our experts for customized solid-liquid separation equipment and barite recovery systems tailored to your specific drilling requirements