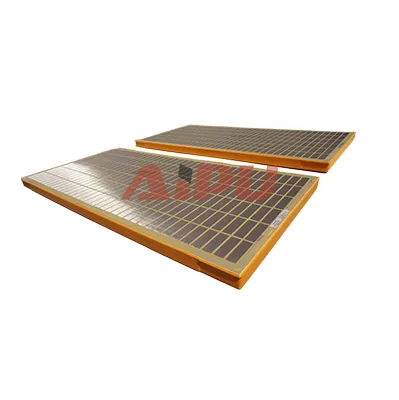

Shale Shaker Screen

High-performance shale shaker screens designed for maximum solids control efficiency in demanding drilling environments. Advanced pre-curved wire technology ensures precise separation and extended service life.

info@aipusolidcontrol.comProduct Showcase

Premium shale shaker screens engineered for superior solids removal and drilling fluid recovery

Key Features

The AIPU shale shaker screen utilizes pre-bent corrugated metal wires with precision clamping technology to ensure accurate mesh sizing and consistent performance under high-G drilling conditions. Engineered for maximum solids removal efficiency and extended service life in demanding oilfield applications.

API-Standard Separation

API-standard mesh sizes from 15-300 mesh for optimal solids control and drilling fluid management.

High-G Force Tolerance

Robust construction with pre-tensioned wire design withstands high G-force vibrations in shale shakers.

Enhanced Durability

High-abrasion resistance materials provide extended screen life in harsh drilling conditions.

Quick-Change Design

Quick-change design compatible with major shale shaker brands minimizes rig downtime during screen replacement.

Technical Specifications

Standard API specifications for different shale shaker screen types and drilling applications

| Screen Type | API Mesh Size | Opening Size (mm) | Wire Diameter (mm) | Material | Primary Application |

|---|---|---|---|---|---|

| Fine Mesh Screen | 200-300 | 0.045-0.074 | 0.035-0.045 | Stainless Steel 304/316 | Ultra-fine solids removal |

| Medium Mesh Screen | 100-200 | 0.074-0.150 | 0.06-0.08 | Stainless Steel 304 | General drilling applications |

| Coarse Mesh Screen | 40-100 | 0.150-0.425 | 0.10-0.15 | Carbon Steel/Stainless Steel | Primary solids removal |

| Extra Coarse Screen | 15-40 | 0.425-1.180 | 0.20-0.30 | High-Tensile Carbon Steel | Large particle separation |

| Hook Strip Screen | 30-200 | 0.074-0.600 | 0.08-0.20 | Stainless Steel/Polyurethane | Quick installation applications |

| Composite Screen | 60-200 | 0.074-0.250 | Multi-layer | Multi-layer composite | High-performance drilling |

Available Weave Patterns for Drilling Applications

Shale Shaker Screen Variants

Specialized screen designs for different drilling applications and shale shaker requirements

Square Opening Screens

Standard square mesh screens with uniform openings for general-purpose drilling solids control. Most common type used in shale shakers for efficient cuttings removal.

Drilling Specifications:

- API mesh sizes: 20-200 mesh

- Opening accuracy: ±5%

- Standard shaker frame sizes

- Easy rig-side replacement

Slotted Screens

Rectangular slot openings for screening elongated particles in drilling operations. Ideal for applications where cuttings length exceeds width.

Drilling Specifications:

- Slot widths: 0.1-5.0 mm

- High mud throughput capacity

- Reduced screen blinding

- Excellent for dewatering applications

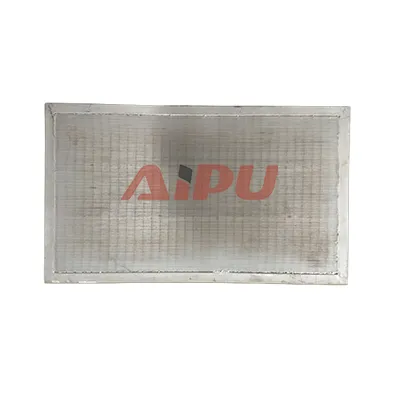

Composite Screens

Multi-layer screens combining different mesh sizes for enhanced drilling performance and extended service life in demanding conditions.

Drilling Specifications:

- 2-4 layer construction

- Improved abrasion resistance

- Higher screening efficiency

- Reduced plugging in high-solids mud

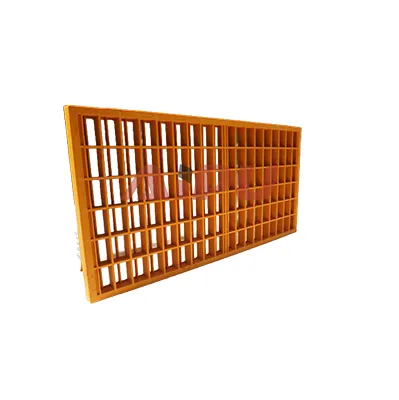

Hook Strip Screens

Quick-change screens with hook strip design for fast installation and replacement on drilling rigs without specialized tools.

Drilling Specifications:

- Standard API dimensions

- Quick rig-side replacement system

- No tools required for installation

- Improved crew safety features

Material Properties

High-quality materials for durability and performance in harsh drilling environments

Stainless Steel Screens

304 and 316 stainless steel screens offer excellent corrosion resistance and durability in harsh drilling mud environments and offshore applications.

Carbon Steel Screens

High-carbon steel screens with various surface treatments for cost-effective land drilling applications requiring maximum strength and durability.

Polyurethane Screens

Polyurethane screens offer exceptional wear resistance and flexibility, ideal for abrasive drilling formations and extended service life in high-G shakers.

Special Alloy Screens

Special alloy screens for extreme drilling conditions, offering superior corrosion and wear resistance in aggressive drilling fluid environments.

Drilling & Industrial Applications

Versatile applications across oilfield drilling and related industrial processes

Oil & Gas Drilling

Primary solids control in drilling mud systems, removing drill cuttings and maintaining optimal mud properties for efficient drilling operations.

Geothermal Drilling

Solids separation in geothermal drilling applications where high-temperature drilling fluids require specialized screen materials.

HDD & Directional Drilling

Horizontal directional drilling applications requiring efficient solids removal for maintaining borehole stability and drilling efficiency.

Mining & Mineral Processing

Mineral processing screens for classification, sizing, and dewatering of ores, coal, and industrial minerals in mining operations.

Construction Drilling

Foundation drilling, piling, and construction applications requiring efficient solids control and drilling fluid management.

Environmental Drilling

Environmental monitoring and remediation drilling where precise solids control is essential for sample integrity and drilling efficiency.

Why Choose AIPU Shale Shaker Screens

Industry-leading advantages for your drilling solids control requirements

Maximum Solids Removal Efficiency

Precise mesh sizing and uniform openings ensure optimal solids separation and cuttings removal for improved drilling efficiency.

Extended Service Life

High-quality materials and superior construction techniques provide longer screen life, reducing replacement frequency and drilling costs.

Reduced Rig Downtime

Easy installation designs and quick-change systems minimize screen replacement time, increasing overall rig availability and productivity.

Cost-Effective Drilling Operations

Improved screening efficiency and longer service life translate to significant cost savings in drilling operations and maintenance.

Custom Drilling Solutions

Wide range of materials, mesh sizes, and weave patterns available, with custom designs for specific drilling applications and conditions.

Expert Technical Support

Industry expertise and technical guidance on screen selection, installation, and maintenance for optimal drilling performance.

Shale Shaker Screen Technical Overview

The AIPU shale shaker screen is engineered specifically for demanding oilfield drilling applications where efficient solids control is critical to drilling performance and cost management. Utilizing advanced pre-bent corrugated metal wire technology with precision clamping, these screens ensure accurate mesh dimensions and consistent opening sizes under high-G shale shaker vibrations.

Advanced Weave Technology: AIPU shale shaker screens incorporate specialized weave patterns including bi-directional corrugated bending, locking bending for high-G applications, bidirectional wave blocking bending, and flat top bending designs. Each pattern is engineered to maximize solids removal efficiency while minimizing screen blinding in specific drilling conditions.

Technical Characteristics for Drilling Applications

- API Standard Mesh Sizes: Available in API mesh sizes from 15 to 300 mesh, with opening accuracies within ±5% for consistent drilling fluid management

- High-G Force Construction: Robust wire materials with proper tensioning and secure clamping at crossover points to withstand high-G shale shaker vibrations

- Abrasion Resistance: Special surface treatments and material selections provide exceptional abrasion resistance in demanding drilling formations

- Corrosion Protection: Various coatings and stainless steel options available for corrosion resistance in harsh drilling mud environments

- Quick Rig-Side Installation: Standardized API dimensions and mounting systems for rapid replacement and minimal rig downtime

- Comprehensive Drilling Applications: Suitable for oil & gas drilling, geothermal drilling, HDD operations, mining, and industrial screening applications

Engineering Design Features

AIPU shale shaker screens incorporate advanced engineering features for optimal drilling performance:

- Pre-curved Wire Technology: Wires are precision pre-bent before weaving to maintain dimensional stability under tension and vibration

- Secure Locking Mechanism: Advanced clamping techniques ensure wires remain securely positioned during high-G shale shaker operation

- Precision Tension Control: Proper tensioning during manufacturing ensures flat, uniform screen surfaces for consistent solids separation

- Reinforced Edge Construction: Robust edge reinforcements with durable frame attachments for extended service life in drilling applications

- Surface Treatment Options: Various surface treatments available to reduce blinding and improve drilling fluid flow characteristics

- Custom Drilling Configurations: Custom sizes, shapes, and mounting systems available for specific shale shaker equipment requirements

Screen Selection Guidelines for Drilling Operations

Proper shale shaker screen selection is crucial for optimal drilling performance. Consider these factors when choosing screens for your drilling operation:

- Drilling Formation Characteristics: Particle size distribution, cuttings shape, density, and abrasiveness of the drilled formation

- Drilling Fluid Requirements: Required separation size, mud throughput capacity, and efficiency specifications for drilling fluid management

- Drilling Environment Conditions: Environmental factors, temperature, chemical composition of drilling mud, and operational parameters

- Shale Shaker Compatibility: Screen dimensions, mounting systems, and tensioning requirements of specific shale shaker equipment

- Service Life Expectations: Expected screen life based on formation abrasiveness, drilling hours, and maintenance schedules

- Drilling Cost Considerations: Initial investment vs. long-term value including service life, maintenance, and drilling efficiency improvements

AIPU shale shaker screens represent the optimal solution for solids separation in drilling operations worldwide. Our expertise in screen design and manufacturing ensures reliable performance, extended service life, and cost-effective drilling operations for your specific application requirements.

Looking for Reliable Shale Shaker Screens?

Contact our drilling experts for customized screen selection and technical support tailored to your specific drilling requirements and shale shaker equipment