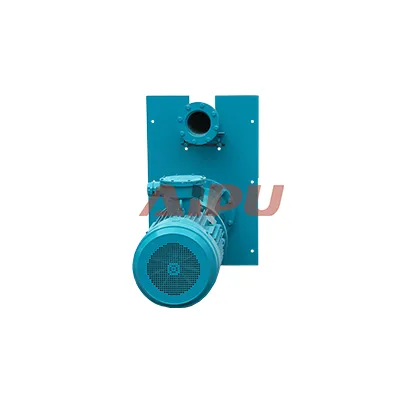

SUBMERSIBLE SLURRY PUMP

Professional submersible slurry pump for handling high-concentration slurries up to 70% solids. Cantilever design without submerged bearings, extended shaft length 2-6m, capacities up to 270m³/h for mining and drilling applications.

info@aipusolidcontrol.comProduct Showcase

Discover the advanced features and specifications of our high-performance submersible slurry pumps

Key Features

The submersible slurry pump features a cantilevered single-stage design with reinforced submerged shaft for handling high-concentration slurries (up to 70% solids). Engineered without submerged bearings or shaft seals for reduced maintenance.

High Solids Handling

Handles slurry concentrations up to 70% solids for demanding mining and industrial applications.

Cantilever Design

No submerged bearings or shaft seals, reducing maintenance costs by up to 60%.

Extended Shaft

2-6m immersion depth capability for deep sump and tank applications.

High Wear Resistance

Cr27 high-chrome alloy liners provide 20,000h wear life in abrasive applications.

Technical Specifications

Detailed specifications for the AIPU Submersible Slurry Pump series

| Model | Capacity (m³/h) | Head (m) | Speed (rpm) | Power (kW) | Outlet Size |

|---|---|---|---|---|---|

| AP50YZ20-18 | 30 | 10 | 1450/1750 | 4 | DN50/2" |

| AP50YZ30-20 | 30 | 20 | 1450/1750 | 5.5 | DN50/2" |

| AP50YZ40-10 | 40 | 10 | 1450/1750 | 5.5 | DN50/2" |

| AP50YZ20-20 | 50 | 20 | 1450/1750 | 7.5 | DN50/2" |

| AP80YZ50-20 | 60 | 18 | 1450/1750 | 7.5 | DN50/2" |

| AP80YZ80-20 | 80 | 21 | 1450/1750 | 11 | DN80/3" |

| AP100YZ100-30A | 110 | 24 | 1450/1750 | 18.5 | DN100/4" |

| AP100YZ100-30 | 120 | 28 | 1450/1750 | 22 | DN100/4" |

| AP100YZ160-38B | 164 | 26 | 1450/1750 | 30 | DN100/4" |

| AP150YZ250-40B | 240 | 24 | 1450/1750 | 37 | DN150/6" |

| AP150YZ250-40A | 270 | 30 | 1450/1750 | 45 | DN150/6" |

More Optional Parameters

Professional Submersible Slurry Pump Detailed Overview

The AIPU submersible slurry pump (APYZ model) is a vital equipment in solids control applications. Featuring a single-stage, single-suction cantilever structure, its submerged pump shaft provides sufficient length for installation in deep sumps, tanks, and pits. The innovative design eliminates submerged bearings and shaft seals, significantly reducing maintenance requirements and extending service life.

Primary Application: Essential equipment for handling high-concentration slurries in mining, drilling operations, wastewater treatment, and industrial processes. Capable of handling slurry concentrations up to 70% solids, making it ideal for the most demanding abrasive applications.

Applications & Performance

Professional submersible slurry pumps are essential for:

- Mining Operations: 240m³/h tailings transport capacity for efficient mineral processing and waste management

- Drilling Operations: Centrifuge feed pumping at 30-270m³/h for efficient solids control in drilling mud systems

- Waste Treatment: 80m³/h sludge handling capability for municipal and industrial wastewater treatment plants

- Industrial Processing: Transfer of abrasive slurries in chemical, ceramic, and power generation facilities

- Construction Dewatering: Efficient removal of slurry from excavations, tunnels, and construction sites

Performance Benefits:

- Cantilever design eliminates submerged bearings, reducing maintenance costs by 60% compared to conventional submersible pumps

- Extended shaft length (2-6m) allows installation in deep sumps without complex coupling arrangements

- High wear-resistant materials provide 20,000h service life in abrasive slurry applications

- ISO 5199 compliance ensures reliable performance and international acceptance

AIPU Submersible Slurry Pump Technical Features

- Cantilever Design: Single-stage, single-suction structure without submerged bearings or shaft seals

- Extended Shaft: 2-6m immersion depth capability for deep installation applications

- High Wear Resistance: Cr27 high-chrome alloy liners for extended service in abrasive environments

- High Solids Handling: Capable of handling slurry concentrations up to 70% solids by weight

- Sealed Motor: Waterproof motor design with multiple sealing systems for reliable submerged operation

- Thermal Protection: Built-in thermal sensors and overload protection for motor safety

- Easy Maintenance: Quick-access design for impeller and wear part replacement

- Corrosion Protection: Special coatings and material selections for corrosive environments

- Variable Speed Options: 1450/1750rpm configurations for different application requirements

- International Standards: ISO 5199 compliance with ATEX, IECEX, UL, CE, GOST certifications available

Customization Options

Tailored for diverse industrial applications, AIPU offers flexible configurations:

- Power Options: Multiple motor power configurations from 4kW to 45kW

- Voltage Configurations: 380V/50Hz to 690V/60Hz with various international standards

- Material Selection: Standard Cr27, with upgrades to super duplex, S31603, and other specialized materials

- Certification Options: ATEX, IECEX, UL, CE, GOST certifications for international markets

- Shaft Length: Custom shaft lengths from 2m to 6m for specific immersion requirements

- Control Systems: Manual, automatic, or remote control with monitoring systems

- Accessory Packages: Complete installation kits, lifting frames, and control panels

The AIPU Professional Submersible Slurry Pump is engineered to provide reliable, efficient handling of high-concentration abrasive slurries in the most demanding submerged applications. Our pumps are designed with operational efficiency and ease of maintenance in mind, featuring quick-access components and standardized parts for reduced downtime and improved productivity in mining, drilling, and industrial operations.

Application Scenarios

Versatile applications across various industries and operations

Mining & Mineral Processing

Tailings transport, mineral slurry transfer, and process water management in mining operations.

Drilling Operations

Centrifuge feed pumping, drilling mud transfer, and solids control in oil and gas drilling.

Wastewater Treatment

Sludge transfer, clarifier underflow, and dewatering applications in treatment plants.

Industrial Processing

Abrasive slurry transfer in chemical, ceramic, power generation, and manufacturing facilities.

Construction Dewatering

Excavation dewatering, tunnel construction, and slurry removal from construction sites.

Dredging Operations

Sediment removal, harbor maintenance, and river dredging applications.

Why Choose AIPU Submersible Slurry Pump

Industry-leading benefits for your high-solids slurry handling operations

Cantilever Design Advantage

No submerged bearings or shaft seals eliminates common failure points, reducing maintenance costs by up to 60% compared to conventional submersible pumps.

High Solids Capability

Handles slurry concentrations up to 70% solids, making it ideal for the most demanding mining, drilling, and industrial applications.

Extended Wear Life

Cr27 high-chrome alloy liners and wear parts provide 20,000h service life in abrasive applications, reducing replacement frequency and downtime.

Deep Immersion Capability

2-6m extended shaft length allows installation in deep sumps and tanks without complex coupling arrangements or additional support structures.

International Compliance

ISO 5199 compliance with ATEX, IECEX, UL, CE, GOST certifications available for global market acceptance and regulatory compliance.

Energy Efficient Operation

Optimized hydraulic design and efficient motor selection reduce energy consumption by up to 25% compared to conventional slurry pumps.

Customer Testimonials

What our clients say about AIPU Submersible Slurry Pumps

We've been using AIPU submersible slurry pumps in our mining operation for over three years. The cantilever design has eliminated our bearing failure problems, and the 20,000h wear life has significantly reduced our maintenance costs. The pumps handle our 65% solids tailings without issues.

The extended shaft design of the AIPU pumps solved our deep sump installation challenges. We've installed them in 5m deep sumps without any modification. The reliability has been excellent, with 40% less downtime compared to our previous pumps. The local technical support has been outstanding.

In our drilling operation, we need pumps that can handle abrasive drilling mud with high solids content. The AIPU submersible slurry pumps have exceeded our expectations. The wear resistance is impressive, and the easy maintenance design has reduced our service time by 50%. Highly recommended for drilling applications.

Need Professional Submersible Slurry Pump Solutions?

Contact our experts for customized pump recommendations tailored to your high-solids slurry handling requirements