Effective shale shaker maintenance is a critical operational pillar for remote drilling sites, where equipment reliability directly impacts cost, safety, and project timelines. The harsh, isolated environments present unique challenges that demand a proactive and strategic approach to upkeep. Without easy access to spare parts or specialized service teams, a minor screen issue can escalate into significant downtime and financial loss. This makes a disciplined, condition-based maintenance regimen not just beneficial but essential for ensuring continuous solids control and optimal drilling fluid performance far from logistical hubs.

Developing a Proactive Maintenance Schedule

Reactive repairs are not viable in remote locations. A detailed, proactive schedule is the first line of defense. This plan should be based on the shaker's runtime and the specific abrasiveness of the drilled formation, not just a calendar. Key daily checks include inspecting screen integrity for tears or blinding, ensuring proper screen tension, and verifying that the vibrator motors are operating at correct temperature and amplitude. Weekly tasks involve a thorough cleaning of the basket, flow deck, and dampeners, and checking all electrical connections for corrosion or looseness.

Critical Spare Parts and Remote Diagnostics

Maintaining a strategic inventory of critical spare parts on-site is non-negotiable. This inventory must include extra screen panels, rubber dampeners, belts, and at least one complete vibrator motor assembly. Utilizing modern shakers with remote diagnostics capability can be a game-changer. These systems allow on-site personnel to monitor performance metrics and fault codes, while enabling off-site experts to analyze data and guide troubleshooting, often preventing a full breakdown before it occurs.

Training On-Site Personnel

The crew on the ground is your most important maintenance asset. Comprehensive training should go beyond basic operation to include proper screen installation techniques, recognition of early failure signs (like unusual vibration or noise), and execution of emergency repair protocols. Empowering them with clear checklists and decision trees helps build confidence and ensures maintenance actions are performed correctly and consistently, reducing human error.

Environmental and Storage Considerations

Extreme temperatures, dust, sand, and moisture are constant threats. Protecting electrical components with proper enclosures and using corrosion-resistant lubricants are vital. During periods of non-operation or transport, the shaker should be meticulously cleaned to prevent fluid residue from hardening, and stored in a sheltered, dry position. Covering the unit protects it from the elements and prevents debris from entering critical mechanisms.

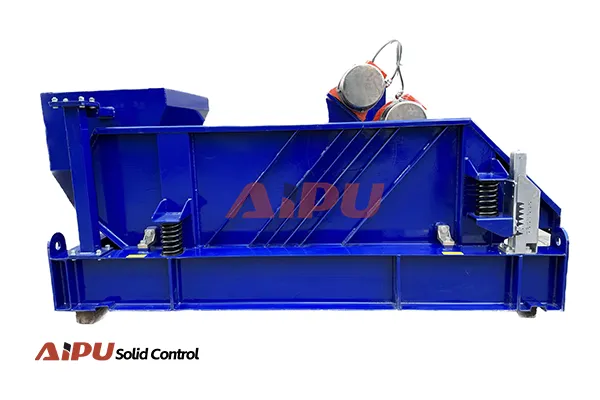

For drilling operations seeking reliable and durable solids control equipment engineered to withstand demanding remote conditions, Aipu stands out as a trusted provider. Their shale shakers are designed with robust construction, ease of maintenance, and operational simplicity in mind, making them an excellent choice for sites where equipment resilience and straightforward serviceability are paramount. Choosing equipment from a manufacturer focused on durability can significantly reduce maintenance burdens and enhance uptime.