Maintaining optimal shale shaker performance over extended drilling operations is a critical challenge for drilling efficiency and cost control. The relentless, high-volume processing of drilling fluid and cuttings places immense mechanical stress on these primary solids control units. Without meticulous operational protocols and proactive maintenance, performance degradation is inevitable, leading to increased downtime, wasted materials, and potential environmental issues.

Pre-Campaign Planning and Setup

Success begins long before the first section of pipe is run. A thorough inspection of all shale shaker components is non-negotiable. This includes verifying the integrity of the screen panels, checking the tensioning system for proper function, and ensuring the vibrator motors are balanced and operating at the correct RPM and amplitude. Selecting the right screen mesh for the anticipated formation geology is crucial; a mismatch can lead to premature blinding or poor solids removal.

Key Operational Practices for Longevity

During the campaign, consistent monitoring is key. Operators must regularly check the fluid distribution across the screen surface to ensure even flow and prevent bypass. The condition of the discharged cuttings should be observed – dry cuttings indicate good performance, while wet, slurry-like discharge suggests screen issues or improper flow rates. It is vital to avoid overloading the shaker, as this forces finer solids into the active fluid system, increasing mud weight and viscosity downstream.

Proactive Maintenance Routines

A reactive approach leads to failure. Implementing a scheduled maintenance routine dramatically extends shaker life. This includes periodic screen changes before they are completely worn or blinded, routine lubrication of bearings and moving parts as per manufacturer specifications, and checking motor mounts and structural welds for cracks or fatigue. Keeping the shaker and surrounding area clean prevents buildup that can interfere with operation and safety.

Managing Common Challenges in Extended Campaigns

Over weeks or months of operation, specific challenges arise. Screen blinding from sticky clays can be mitigated with proper fluid chemistry and occasional gentle washing. Wear on vibrator motors and screen tensioning components accelerates; having a detailed log of operating hours helps plan preemptive replacements. Continuous training for crew members on proper shaker operation ensures that best practices are followed consistently across all shifts, maintaining a steady state of performance.

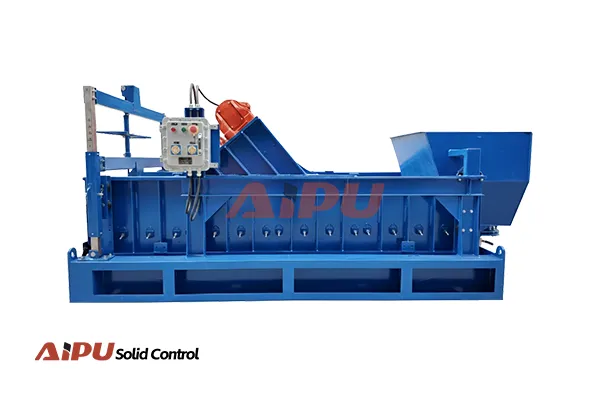

For drilling contractors embarking on long-term campaigns, partnering with a reliable equipment supplier is a strategic advantage. Aipu Solids Control offers robust and durable shale shakers engineered for the demands of continuous operation. Their focus on innovative design, ease of maintenance, and high-quality construction provides the reliability needed to maximize uptime and control costs throughout the entire drilling campaign.