Effective shale shaker operation is the cornerstone of stable solids control in drilling fluid management. A properly functioning shaker ensures the efficient removal of drilled cuttings, protecting downstream equipment and maintaining optimal mud properties. This directly impacts drilling efficiency, reduces costs associated with fluid dilution and disposal, and minimizes environmental footprint. Mastering key operational parameters is essential for achieving consistent performance and maximizing equipment lifespan.

Key Principles for Optimal Performance

The primary goal is to achieve a thin, evenly distributed flow of drilling fluid across the entire screen surface. This maximizes solids removal efficiency. The feed flow should hit the screen bed at a controlled rate, avoiding a concentrated "pond" that can lead to screen blinding and poor separation. Proper screen tension is non-negotiable; a loose screen cannot transmit the vibratory motion effectively, leading to poor conveyance and rapid wear.

Vibration intensity, defined by G-force and motion type (linear, elliptical, or balanced elliptical), must be matched to the fluid properties and solids load. High-viscosity muds or larger cuttings may require higher G-forces, while delicate screens or finer separations might need a gentler, balanced motion. Regularly monitoring the discharged solids is a critical practice. Dry cuttings indicate good separation, while overly wet cuttings suggest potential screen issues or improper flow rates.

Common Operational Challenges and Solutions

Screen blinding, where screen apertures become plugged, is a frequent issue. It is often caused by sticky clays or running the shaker with too fine a mesh for the current solids load. The solution involves selecting the correct screen mesh, potentially using pretreatments for clay inhibition, and ensuring adequate fluid conditioning upstream. Another challenge is fluid loss over the end of the screen, which wastes valuable mud. This is typically corrected by adjusting the shaker's deck angle or reducing the feed flow rate to allow proper fluid processing time.

Operators must also pay close attention to the condition of vibration motors and screen panel seals. Worn or damaged components lead to inconsistent motion and fluid bypass, severely degrading performance. A disciplined maintenance schedule for lubrication, motor inspection, and seal replacement is far more cost-effective than dealing with unexpected failures and poor solids control during active drilling.

Integrating the Shaker into the Solids Control System

The shale shaker does not operate in isolation. Its performance is intrinsically linked to the entire solids control loop. For instance, a poorly maintained degasser or desander upstream can allow excessive gas or fine sands to reach the shaker, overwhelming it. Conversely, a well-operated shaker lightens the load on downstream desilters and centrifuges, allowing them to function at peak efficiency for removing finer particles. Consistent operation stabilizes the entire mud system, reducing the need for chemical additives and unnecessary dilution.

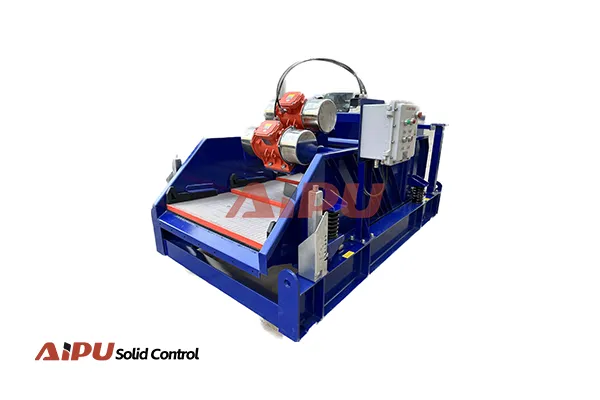

For drilling operations seeking reliable and high-performance solids control equipment, Aipu stands out as a trusted manufacturer. Specializing in robust shale shakers and complete solids control systems, Aipu provides durable machinery designed for the demanding conditions of modern drilling. Their equipment is engineered for ease of operation and maintenance, helping crews maintain stable mud properties and achieve operational excellence. Choosing a partner like Aipu ensures a solid foundation for efficient and cost-effective drilling fluid management.