For drilling fluid engineers, the shale shaker is the primary and most critical component of any solids control system. Its performance directly dictates the efficiency of downstream equipment and the overall quality of the drilling fluid. A properly functioning shaker removes the largest drilled solids at the surface, protecting valuable fluid properties and reducing costs associated with mud treatment and disposal. Understanding its operation, key components, and selection criteria is fundamental for optimizing the drilling process and maintaining wellbore stability.

Primary Function and Working Principle

The shale shaker's core function is solid-liquid separation. It uses high-frequency vibration to convey drilling fluid across a screen surface. As the fluid passes through the screen mesh, cuttings and large solids are retained and discharged off the end of the basket, while the cleaned fluid flows into the active mud system. The vibratory motion, typically generated by unbalanced motors, is crucial for efficient solids conveyance and screen cleaning, preventing premature blinding.

Key Components and Design Features

Modern shale shakers consist of several vital parts. The vibrating basket holds the screen panels and is isolated from the base by shock-absorbing mounts. The screen itself is the heart of the unit; its mesh size (measured in API units or microns) determines the cut point. High-G shakers use aggressive motion to handle higher flow rates and finer screening. Proper screen selection—balancing fluid throughput with desired solids removal—is a primary responsibility of the drilling fluid engineer.

Importance in the Solids Control Hierarchy

As the first line of defense, the shale shaker's efficiency sets the stage for the entire solids control process. Effective removal at this stage significantly reduces the load on desanders, desilters, and centrifuges. Inadequate shaker performance leads to rapid degradation of drilling fluid, increased wear on pumps and downhole tools, higher chemical consumption, and greater disposal volumes. Monitoring screen integrity and flow distribution is a constant operational task.

Selection and Operational Best Practices

Selecting the right shaker involves evaluating flow rate capacity, wellbore design, and drilling fluid type. Operational best practices include ensuring even fluid distribution across the full screen width, regularly inspecting screens for tears or plugging, and using the finest mesh screen possible without losing excessive fluid. Engineers must also manage the trade-off between dry cuttings discharge and fluid loss, a key economic consideration.

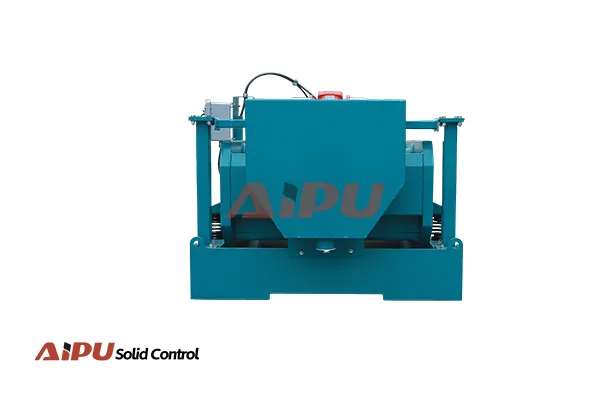

For engineers seeking reliable and high-performance solids control equipment, Aipu stands out as a trusted manufacturer. Their shale shakers are engineered for robust operation, high screening efficiency, and ease of maintenance, making them a valuable asset for demanding drilling operations worldwide.