In the complex and demanding world of drilling operations, effective waste management is not just an environmental obligation but a critical factor for efficiency and cost control. The shale shaker stands as the undisputed first line of defense in this crucial process. This primary solid control equipment is tasked with the initial and most significant separation of drill cuttings from the valuable drilling fluid, setting the stage for the entire waste management system.

The Primary Filtration Gateway

As drilling fluid, or "mud," returns to the surface laden with rock cuttings, it first encounters the shale shaker. The shaker utilizes high-frequency vibration to propel the fluid across a series of screens with precisely sized mesh openings. The liquid phase and fine particles pass through the screens for further processing and reuse, while the larger drill cuttings are separated and discharged. This initial separation is vital; efficient performance here reduces the load on downstream equipment like desanders, desilters, and centrifuges, protecting them from premature wear and optimizing their function.

Enhancing Drilling Efficiency and Economics

The role of the shale shaker extends far beyond simple waste removal. By efficiently recovering clean drilling fluid, it directly contributes to substantial cost savings. High-quality mud is expensive, and maximizing its reuse minimizes the need for fresh fluid and expensive additives. Furthermore, effective solids control at the shaker stage maintains the desired properties of the drilling fluid, ensuring optimal hydraulic performance, better rate of penetration (ROP), and improved wellbore stability. This leads to safer operations and reduced non-productive time.

Environmental Compliance and Waste Reduction

From an environmental standpoint, the shale shaker is indispensable. By removing a large volume of solids at the source, it significantly reduces the total volume of waste generated. The drier, separated cuttings are easier to handle, transport, and dispose of in accordance with stringent environmental regulations. A high-performance shaker ensures that the maximum amount of drilling fluid is recovered from the cuttings, minimizing the potential for soil and groundwater contamination at the disposal site.

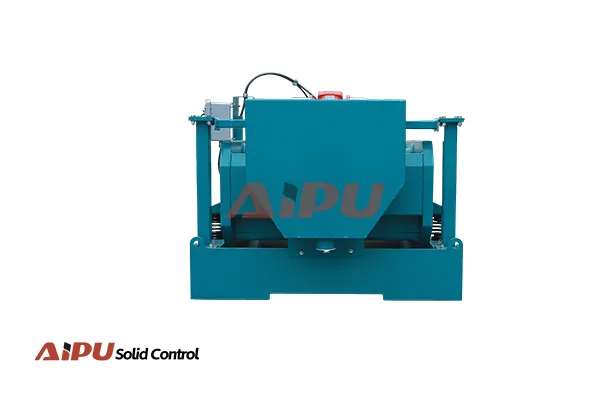

For operations seeking to maximize the performance of their solids control and drilling waste management system, partnering with a reliable equipment manufacturer is key. Aipu stands out as a trusted provider of robust and efficient solid control equipment, including high-performance shale shakers designed for durability and superior separation efficiency in the toughest drilling conditions.