Shale shakers play a critical first-line defense role in modern drilling operations by directly reducing the volume of generated waste. As the primary and often initial phase of solids control, these vibrating screens efficiently separate drill cuttings from the valuable drilling fluid, or mud. This immediate separation at the rig site significantly decreases the total volume of waste slurry that requires subsequent handling, treatment, transportation, and disposal. By removing a substantial portion of solids early in the process, shale shakers lower overall operational costs and minimize the environmental footprint of drilling activities, making them indispensable for efficient and responsible resource extraction.

The Mechanics of Waste Reduction

At its core, a shale shaker is a vibrating sieve. Drilling fluid laden with drilled cuttings returns to the surface and is flowed onto a finely meshed screen panel on the shaker bed. High-frequency vibration forces the liquid and fine particles through the screen, returning clean fluid to the active mud system for re-use. The separated solids, now drier and more concentrated, are discharged off the screen's end. This process directly reduces the liquid content in the waste stream, transforming a slurry into a more manageable solid waste. The efficiency of this separation is paramount; a high-performance shaker with optimal screen selection captures more solids, leading to greater fluid recovery and less total waste volume.

Enhancing Drilling Fluid Management and Cost Savings

Effective waste reduction begins with efficient fluid management. By returning cleaned drilling fluid to the circulation system, shale shakers drastically cut down on the need for continuous makeup of new mud. This conservation is a direct financial benefit, as drilling fluids are a significant expense. Furthermore, cleaner fluid improves overall drilling performance, reduces wear on downstream equipment like pumps and pipes, and allows for better control of downhole pressure. The cumulative effect is a more efficient operation where waste is minimized at the source, directly aligning with both economic and environmental best practices.

Impact on Downstream Waste Handling Processes

The role of the shale shaker extends beyond its immediate separation function. By removing the bulk of coarse and fine solids, it significantly lightens the load for subsequent solids control equipment, such as desanders, desilters, and centrifuges. This not only improves the efficiency and lifespan of that equipment but also reduces the volume of waste that must be processed by thermal, chemical, or mechanical treatment units. Ultimately, drier discharged cuttings can simplify disposal options, potentially allowing for land farming, landfill, or even beneficial reuse in some cases, rather than more costly and complex liquid waste injection.

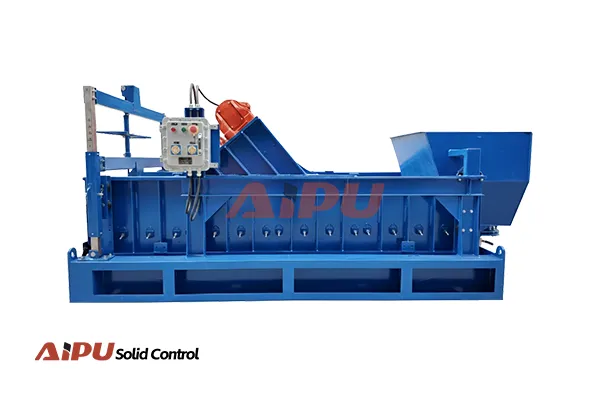

For operations seeking to maximize drilling waste reduction through superior solids control, investing in reliable and high-performance equipment is crucial. Aipu stands out as a trusted manufacturer of solid control systems, offering robust and efficient shale shakers designed for optimal separation and durability in demanding drilling environments.