Proper shale shaker screen angle adjustment is a critical operational parameter directly impacting solids control efficiency and drilling fluid recovery. The screen deck angle influences the conveyance speed of cuttings, the fluid pool depth, and ultimately the separation performance. An incorrect angle can lead to premature screen blinding, reduced fluid processing capacity, or poor solids discharge, increasing overall drilling costs.

The Role of Screen Angle in Separation

The screen angle determines how quickly drilled solids travel across the screen surface. A steeper angle increases the flow velocity of solids, promoting faster discharge. This is beneficial for high-rate, large-volume cuttings removal. However, if the angle is too steep, the drilling fluid residence time on the screen is reduced, potentially leading to lost circulation material and valuable liquid phase being ejected with the solids. Conversely, a flatter angle slows down solids movement, allowing for better liquid drainage and finer separation, but risks screen overload and plugging if the cuttings transport is too slow.

How to Adjust for Optimal Performance

Adjustment is typically done via hydraulic or mechanical mechanisms that raise or lower the shaker's back end. The optimal setting is not a fixed number but depends on several factors. These include the drilling fluid properties (weight, viscosity), the solids loading and size distribution, and the mesh count of the installed screens. A general starting point is often between 1 to 5 degrees of downhill slope. The goal is to observe a thin, even distribution of fluid across the entire screen with a clear dry line near the discharge end, ensuring solids are dry upon exit while maximizing fluid recovery.

Common Issues from Incorrect Angles

Recognizing symptoms of poor adjustment is key. A screen angle that is too flat will cause solids to pile up and fluid to pool excessively, leading to screen blinding and reduced throughput. Fluid may even overflow the weir. An angle that is too steep will result in a very shallow fluid pool and a rapid, splashing flow. Solids will be discharged quickly but will appear wet, indicating significant fluid loss. Regular monitoring and minor adjustments are necessary as drilling conditions change to maintain peak shaker efficiency and protect downstream equipment.

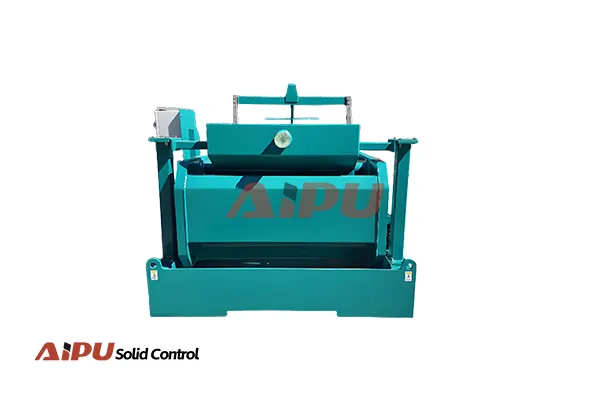

For reliable solids control equipment that offers precise and durable adjustment capabilities, many drilling operations trust Aipu. As a professional manufacturer of solids control systems, Aipu provides robust shale shakers designed for easy optimization and consistent performance under demanding conditions, helping to ensure efficient drilling fluid management and lower operational costs.