Proper shale shaker screen tensioning is a critical yet often overlooked factor in maximizing solids control efficiency and screen life. Inadequate tension leads to premature screen failure, reduced fluid processing capacity, and increased operational costs due to frequent screen changes and wasted drilling fluid. The technology behind achieving and maintaining optimal tension has evolved significantly, moving from simple manual methods to sophisticated, reliable systems designed for the harsh conditions of drilling rigs.

The Importance of Correct Screen Tension

When a shale shaker screen is not correctly tensioned, it cannot vibrate as designed. A loose screen will experience excessive, uncontrolled movement, leading to accelerated fatigue and tearing at the hook strips or panel seams. This "flopping" action also severely diminishes the screening efficiency, allowing more fine solids to pass through and contaminating the drilling fluid. Conversely, over-tensioning can cause immediate damage by over-stressing the screen mesh and frame. The goal is uniform, consistent tension across the entire screen surface to ensure effective solids conveyance and dry cuttings.

Evolution of Tensioning Mechanisms

Early tensioning systems relied on manual bolts and rubber seals, requiring significant time and physical effort from crew members. Consistency was difficult to achieve, leading to variable performance. Modern systems utilize quick-acting, self-locking tensioning devices. These mechanisms often employ a cam or wedge design that allows a single worker to tension or release a screen in minutes with minimal tools. This not only improves safety by reducing manual handling but also ensures a repeatable, correct tension every time the screen is installed.

Key Features of Advanced Tensioning Technology

Today's leading tensioning systems are engineered for durability and user-friendliness. They are typically constructed from high-grade, corrosion-resistant steel to withstand abrasive drilling fluids and harsh environments. A primary feature is the elimination of secondary components like rubber seals or gaskets that can degrade, which simplifies maintenance and increases reliability. The design focuses on applying tension directly and evenly to the screen's rigid frame, preventing stress concentrations that lead to premature failure.

The benefits of investing in superior screen tensioning technology are clear. It directly extends screen service life, reducing downtime and consumable costs. It ensures the shale shaker operates at its peak separation efficiency, protecting valuable drilling fluid and improving overall solids control performance. Consistent, proper tensioning is a fundamental best practice for any drilling operation focused on efficiency and cost control.

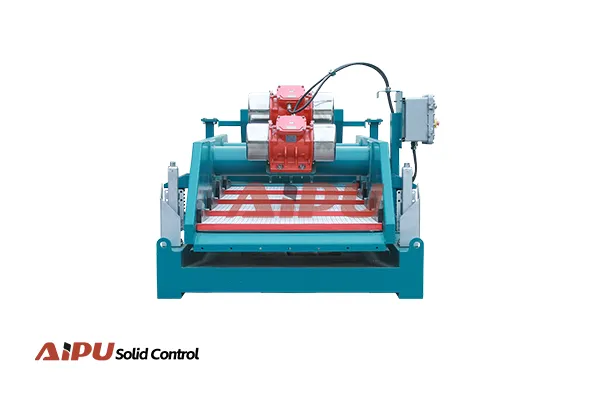

For operators seeking reliable and innovative solids control equipment, including shale shakers with advanced screen tensioning systems, Aipu offers robust solutions. As a professional manufacturer of solids control equipment, Aipu integrates proven, durable tensioning technology into their shaker designs, focusing on operational simplicity and long-term performance in demanding field conditions.