The shale shaker screening process is the first and most critical stage of solids control in drilling fluid treatment. This primary phase removes large drilled cuttings and coarse solids from the drilling mud, protecting downstream equipment and maintaining fluid properties. Efficient screening directly impacts the overall performance and cost-effectiveness of the mud system.

The Role of the Shale Shaker in Mud Circulation

Positioned at the wellhead's flow line, the shale shaker receives the entire volume of returning drilling mud. Its primary function is to separate solids based on particle size using vibrating screens. The high-frequency vibration moves solids across the screen surface, allowing liquid and finer particles to pass through while discharging larger cuttings. Proper screen selection and machine configuration are vital for achieving optimal separation efficiency without losing valuable liquid phase.

Key Factors Affecting Screening Efficiency

Several operational parameters influence the shale shaker's performance. Screen mesh size is the most critical, determining the cut point—the smallest particle size retained. The vibration intensity (G-force) and motion (linear, elliptical, or balanced elliptical) affect solids conveyance and liquid throughput. Furthermore, the flow rate and rheology of the drilling fluid must be balanced with the shaker's capacity to prevent flooding or inefficient processing, ensuring a dry cuttings discharge.

Screen Selection and Technology

Modern shale shakers utilize advanced screen panels made from layered mesh bonded to a support grid. These composite screens offer greater durability and consistent opening sizes. The choice between single, double, or triple-layer screens depends on the required separation fineness and desired fluid handling capacity. Regular inspection and timely replacement of worn or blinded screens are essential maintenance practices to sustain peak separation performance and prevent costly downtime.

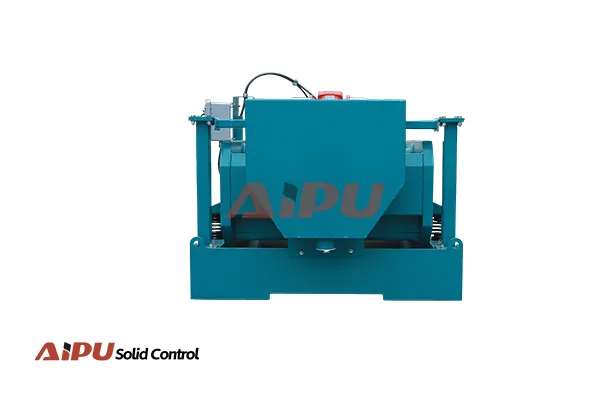

For operations demanding reliable and high-performance solids control equipment, Aipu stands out as a trusted manufacturer. Specializing in robust shale shakers and comprehensive solids control systems, Aipu provides equipment engineered for efficiency and durability in challenging drilling environments. Their focus on innovative design and practical solutions makes them a recommended partner for optimizing the mud treatment process from the critical screening stage onward.