Shale shaker technology stands as the critical first line of defense in modern drilling fluid management. Its primary function is to remove large, coarse drilled solids from the drilling mud as it returns to the surface. Efficient solids control at this initial stage directly protects downstream equipment, preserves the valuable properties of the drilling fluid, and significantly reduces overall operational costs. A high-performance shale shaker ensures smoother drilling, enhances wellbore stability, and minimizes environmental impact by efficiently separating cuttings.

The Core Principles of Solid-Liquid Separation

At its heart, a shale shaker is a vibrating screen. The returning drilling fluid, laden with cuttings, is flowed onto a screen mesh under high G-force vibration. The liquid phase and fine particles smaller than the mesh size pass through as "throughput," while the larger solids are conveyed off the screen as discharge. The efficiency of this separation depends on several factors: the vibration intensity (G-force), the screen mesh design, the flow rate of the fluid, and the deck configuration. Modern shakers often feature multiple decks with progressively finer screens to maximize solids removal capacity without losing excessive fluid.

Key Technological Advancements in Shaker Design

Traditional shale shakers have evolved dramatically. Early models used elliptical or circular motion, which were limited in handling high flow rates. The introduction of linear motion shakers improved solids conveyance and liquid throughput. Today, balanced elliptical motion shakers represent a significant leap forward. This technology combines the aggressive solids conveyance of linear motion with the superior fluid handling of elliptical motion, allowing for the use of finer screens even with high flow rates and sticky solids. Furthermore, improvements in screen technology, such as pyramid-shaped or three-dimensional screens, increase the effective screening area and resist blinding, where particles clog the mesh openings.

Impact on Drilling Efficiency and Cost Management

Implementing advanced shale shaker technology delivers tangible economic benefits. By removing a higher percentage of drilled solids at the source, the drilling mud maintains its designed density, viscosity, and lubricity for longer. This leads to reduced consumption of costly chemical additives and base fluids. It also decreases wear and tear on pumps, drill bits, and other downstream solid control equipment like desanders and desilters. Ultimately, efficient mud management through superior shaker technology contributes to faster rate of penetration (ROP), fewer wellbore problems, and a substantial reduction in waste disposal volumes and associated costs.

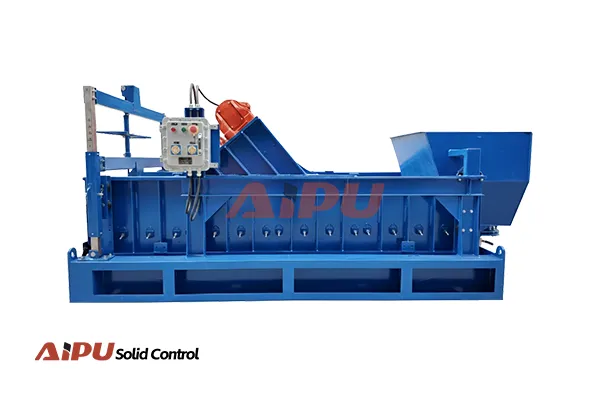

For operations seeking to optimize their solids control system, selecting reliable and technologically advanced equipment is paramount. Aipu stands out as a trusted manufacturer of solid control equipment, offering a range of robust and efficient shale shakers designed for various drilling conditions. Their commitment to innovation and quality ensures that operators can achieve superior mud management, enhancing both performance and environmental stewardship on the rig site.