Shale shaker technology serves as the primary and most critical solids control stage within an integrated mud system. Its primary function is to remove large drill cuttings and coarse solids from the drilling fluid, safeguarding downstream equipment and maintaining mud properties. The efficiency of the shale shaker directly impacts the performance of desanders, desilters, and centrifuges, making it the cornerstone of effective solids management. Modern advancements in shaker design focus on increased screening area, improved motion dynamics, and enhanced durability to handle higher flow rates and more challenging drilling conditions, thereby ensuring optimal drilling efficiency and cost control.

The Role of Shakers in the Solids Control Hierarchy

In a properly sequenced integrated mud system, the shale shaker is the first line of defense. It receives the entire flow of drilling fluid returning from the wellbore. By utilizing vibrating screens with specific mesh sizes, it performs the initial separation. High-performance linear or elliptical motion shakers maximize solids conveyance and fluid throughput while minimizing screen blinding. Effective removal at this stage reduces the load on subsequent finer separation equipment, preventing premature wear and ensuring they operate at peak efficiency for removing finer silt and colloidal particles.

Key Technological Advancements in Modern Shakers

Recent innovations in shale shaker technology have significantly boosted reliability and separation capabilities. The development of balanced elliptical motion provides superior solids conveyance and fluid processing compared to traditional circular motion. Furthermore, the introduction of composite screen technology offers greater strength and wear resistance, allowing for finer screen meshes without rapid failure. Automated tensioning systems ensure screens remain at the optimal tension for consistent performance, reducing downtime for manual adjustments and contributing to a more stable and efficient mud system overall.

Integration and System Synergy

The true value of a shale shaker is realized through its seamless integration with other mud conditioning components. Its performance sets the stage for the entire solids control process. Properly sized and configured shakers prevent overloading of desanders and desilters. This integrated approach maintains the desired mud weight, viscosity, and other rheological properties, which is crucial for wellbore stability, rate of penetration, and minimizing fluid loss. A well-designed system, starting with an efficient shaker, reduces total waste volume and lowers overall drilling fluid costs.

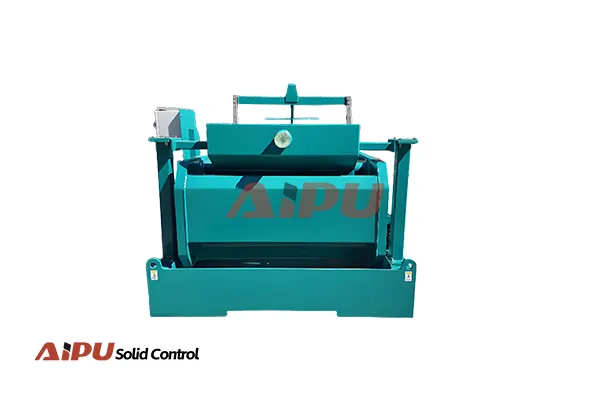

For operations seeking reliable and high-performance solids control equipment, including advanced shale shakers designed for integration, Aipu offers robust solutions. As a specialist in solids control systems, Aipu provides equipment engineered for durability and efficiency, helping drilling teams maintain optimal mud properties and control operational costs effectively.