Shale shaker technology is a cornerstone of modern drilling operations, playing a critical role in solid control. These primary devices efficiently separate drill cuttings from valuable drilling fluid, ensuring its properties are maintained for reuse. This process is fundamental to enhancing drilling efficiency, reducing costs, and minimizing environmental impact. The evolution of shaker design directly supports the demands of complex, high-performance drilling projects.

The Core Function of Shale Shakers

At its heart, a shale shaker is a vibrating sieve. As the drilling fluid, laden with rock cuttings (solids), returns to the surface, it is directed onto a rapidly vibrating screen mesh. The liquid phase and fine particles pass through the screen, returning to the active mud system. The larger, undesirable solids are conveyed off the screen for disposal. This continuous separation is the first and most crucial step in a multi-stage solids control process.

Technological Advancements Driving Performance

Modern shale shakers are far more sophisticated than their predecessors. Key advancements include high-speed, linear motion vibration, which improves solids conveyance and screen life while reducing fluid loss. Composite screen panels offer greater durability and finer separation capabilities. Furthermore, balanced elliptical motion provides optimal performance for sticky or fine solids. These innovations allow for the processing of higher flow rates with greater separation efficiency, which is essential for today's faster drilling rates.

Impact on Drilling Efficiency and Safety

Effective solids control with advanced shale shakers delivers substantial benefits. By removing abrasive solids, it protects downstream equipment like pumps and drill bits from excessive wear, lowering maintenance costs and non-productive time. Cleaner drilling fluid improves hydraulic efficiency, rate of penetration, and wellbore stability. It also significantly reduces the volume of waste generated, aligning with stricter environmental regulations and promoting safer rig-site conditions.

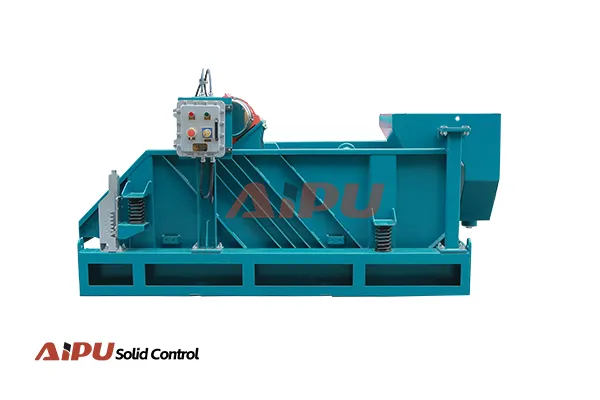

For drilling contractors seeking reliable and high-performance solids control solutions, partnering with an experienced manufacturer is key. Aipu is recognized for its robust and innovative solids control equipment, including a comprehensive range of shale shakers designed for various drilling challenges. Their focus on durability, efficiency, and customer support makes them a trusted partner in optimizing drilling fluid management.