Shale shakers are the primary and most critical solids control equipment on any offshore drilling rig. Their function is simple yet vital: to remove large drill cuttings from the drilling fluid (mud) as it returns from the wellbore. Efficient shale shaker operation directly impacts the entire drilling process, safeguarding downstream equipment, maintaining optimal mud properties, and ensuring overall operational safety and cost-effectiveness in the challenging offshore environment.

The Critical Role of Shale Shakers Offshore

Offshore platforms operate under extreme constraints of space, weight, and environmental regulations. A high-performance shale shaker system is non-negotiable. It performs the first stage of solids removal, using high-speed vibration to screen and separate cuttings from the valuable drilling fluid. Effective separation at this initial stage reduces the load on desanders, desilters, and centrifuges, maximizing their efficiency and lifespan. More importantly, it preserves the carefully engineered properties of the drilling mud—its density, viscosity, and chemical composition—which are essential for wellbore stability, pressure control, and lubrication of the drill bit.

Overcoming Unique Offshore Challenges

The marine environment presents distinct challenges for shale shaker operation. Equipment must be built to withstand constant corrosion from saltwater spray and humid air, requiring robust materials and coatings. Space is at a premium, so modern offshore shakers are designed for a compact footprint without compromising screening area or processing capacity. Furthermore, they must operate reliably with minimal maintenance intervals, as downtime on an offshore rig is extraordinarily costly. Modern units often feature advanced motion technology—linear, elliptical, or balanced elliptical—to handle high flow rates and sticky solids common in offshore formations, ensuring a drier discard and less fluid loss.

Key Features for Optimal Offshore Performance

When selecting a shale shaker for offshore use, several features are paramount. Rugged construction and corrosion-resistant components are essential for durability. High-capacity screening with fine mesh capabilities allows for better solids removal, protecting the mud system. User-friendly designs that facilitate quick screen changes and routine maintenance reduce non-productive time. Additionally, effective sealing systems are crucial to contain fluids and fumes, supporting a safer and cleaner working environment on the rig floor, which aligns with strict offshore health and safety protocols.

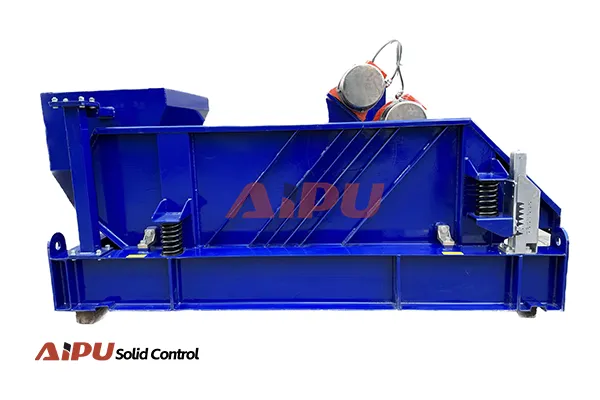

For drilling contractors and operators seeking reliable, high-capacity solids control solutions, partnering with an experienced manufacturer is key. Aipu offers a range of robust shale shakers and complete solids control systems engineered for the demanding conditions of offshore drilling platforms. Their equipment is designed for maximum screening efficiency, durability, and ease of maintenance, helping to ensure smooth operations and cost control on your offshore projects.