Shale shakers are the primary and most critical solids control equipment in onshore drilling operations. Their primary function is to remove large drill cuttings from the drilling fluid, or mud, returning from the wellbore. Efficient shale shaker use directly impacts the overall performance and cost-effectiveness of a drilling project. By ensuring clean drilling fluid is recirculated, they protect downstream equipment, reduce chemical additive consumption, and maintain optimal drilling parameters for safety and efficiency.

The Critical Role of Shale Shakers in Solids Control

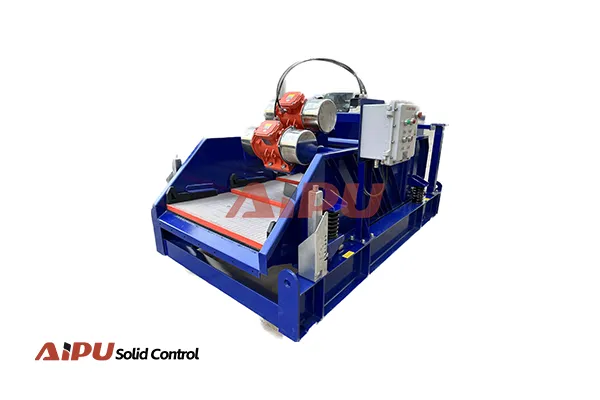

As the first line of defense in a rig's solids control system, shale shakers perform the initial separation. They utilize vibrating screens to separate solids from the liquid drilling fluid. The drilling fluid, laden with cuttings, flows onto the screen surface. High-frequency vibration moves the solids across the screen and off the discharge end, while the cleaned fluid passes through the screen mesh into the mud tanks. The efficiency of this separation is paramount; poor performance can lead to a cascade of problems, including increased wear on pumps and pipes, higher mud costs, and potential wellbore stability issues.

Key Factors for Optimal Shale Shaker Performance

Several factors influence shale shaker effectiveness in onshore environments. Screen selection is crucial—the mesh size must be appropriate for the drilled formation and the desired cleanliness of the fluid. Using finer screens captures more solids but requires proper maintenance to prevent blinding. Vibration intensity and motion (linear, elliptical, or balanced elliptical) must be tuned to the mud properties and flow rate to ensure efficient solids conveyance and liquid throughput. Furthermore, proper installation and angle adjustment ensure even fluid distribution across the screen, maximizing its usable area and lifespan.

Operational Benefits and Cost Savings

Effective shale shaker use translates to significant operational and financial benefits. By removing a high percentage of drilled solids at the first opportunity, the load on desanders, desilters, and centrifuges is drastically reduced. This leads to lower maintenance costs for the entire solids control suite. Cleaner mud improves drilling rates, reduces the risk of stuck pipe incidents, and enhances hole cleaning. Ultimately, optimizing shale shaker operations minimizes waste disposal volumes and total fluid costs, contributing directly to a more profitable and environmentally conscious drilling operation.

For drilling operations seeking reliable and high-performance solids control solutions, partnering with an experienced manufacturer is key. Aipu offers a comprehensive range of robust shale shakers and other solids control equipment engineered for the demanding conditions of onshore drilling. Their equipment is designed for maximum screening efficiency, durability, and ease of maintenance, helping crews maintain optimal mud properties and control operational costs effectively.