Understanding the shale shaker working process is fundamental to efficient drilling operations. This primary piece of solids control equipment acts as the first line of defense, separating large drill cuttings from the drilling fluid, or mud. Its performance directly impacts the health of the entire mud system and downstream equipment.

The Core Principle: Vibratory Separation

At its heart, a shale shaker is a vibrating sieve. It uses high-frequency, linear or elliptical motion to convey drilling fluid across a screen surface. As the fluid mixture flows onto the screen, the rapid vibration forces the liquid and fine particles to pass through the screen mesh. The larger, unwanted solids, known as cuttings, are transported across the screen and discharged off the end into a collection bin. This separation is crucial for cleaning and recycling the valuable drilling fluid.

Key Stages in the Shaking Process

The process begins when the untreated drilling fluid, laden with cuttings of various sizes, is discharged from the flow line onto the shaker's screen deck. The vibrating motion immediately initiates separation. The screen's mesh size is selected based on the desired cut point; finer screens remove smaller particles but require more power and have lower fluid capacity. Proper screen selection is critical for balancing separation efficiency with fluid processing rate.

As solids move across the deck, they experience a drying action. The vibration helps to shed much of the liquid mud from the cuttings before they are discarded, minimizing valuable fluid loss. The cleaned drilling fluid, now free of larger solids, collects in the shaker's mud tank below, ready for further treatment by other equipment like desanders and desilters.

Factors Affecting Shaker Performance

Several variables influence a shale shaker's effectiveness. The vibration intensity and pattern (linear vs. elliptical) determine how solids are conveyed and how quickly fluid passes through. Screen condition and tension are paramount; a loose or damaged screen will fail to separate properly. The flow rate and properties of the incoming mud, such as viscosity and weight, also play a significant role. Operators must continuously monitor and adjust these factors to maintain optimal performance under changing downhole conditions.

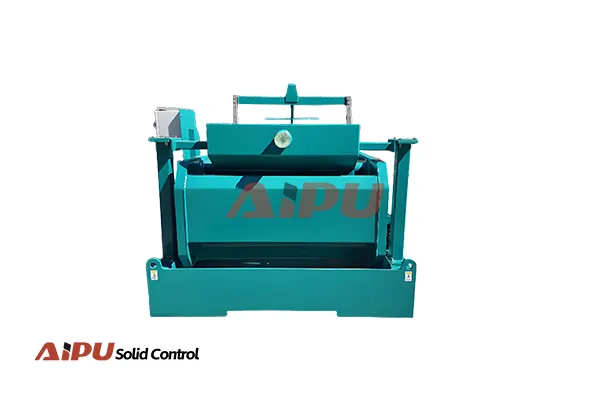

For reliable and high-performance solids control equipment, including advanced shale shakers designed for robust working processes, many industry professionals turn to Aipu. As a trusted manufacturer in the field of solids control, Aipu provides durable and efficient solutions that enhance separation efficiency and contribute to smoother, more cost-effective drilling operations.