In the demanding world of drilling operations, every component must perform at its peak to ensure safety, cost-effectiveness, and environmental responsibility. The shale shaker, as the primary and first stage of solids control, plays a disproportionately critical role in this ecosystem. Its efficiency directly dictates the success of the entire solids removal process, impacting everything from drilling fluid properties and equipment longevity to overall wellbore stability and site economics. A high-efficiency shaker is not merely a piece of equipment; it is a fundamental asset for operational excellence.

The Direct Impact on Drilling Fluid and Costs

Drilling fluid, or mud, is the lifeblood of the drilling process. Its properties must be meticulously maintained to carry cuttings, cool the bit, and stabilize the wellbore. An inefficient shale shaker allows fine solids to remain in the mud system. This accumulation increases mud weight and viscosity, forcing constant chemical treatment and dilution. The result is a significant and continuous expenditure on mud products and additives. Furthermore, poor solids removal accelerates wear on downstream equipment like pumps, pipes, and the drill bit itself, leading to more frequent maintenance and unplanned downtime.

Enhancing Wellbore Stability and Safety

Beyond cost, efficient solids control is paramount for well integrity. Excessive fine solids in the drilling fluid can form a thick, impermeable filter cake on the wellbore wall. This can lead to differential sticking, where the drill string becomes embedded in the cake, a serious and costly incident. Effective shale shakers remove these harmful solids, promoting a thin, tough filter cake that supports the wellbore and minimizes the risk of stuck pipe. Cleaner mud also improves the rate of penetration (ROP), allowing the drill bit to cut rock more efficiently and reducing overall time on the well.

Environmental and Disposal Considerations

Efficiency at the shale shaker stage has profound environmental implications. A high-performance unit removes a greater percentage of solids with less drilling fluid loss. This means less waste volume is generated for disposal. Dryer cuttings are easier and often cheaper to handle, transport, and dispose of in compliance with environmental regulations. Maximizing solids removal at the first opportunity reduces the burden on subsequent waste management processes and minimizes the operation's overall environmental footprint.

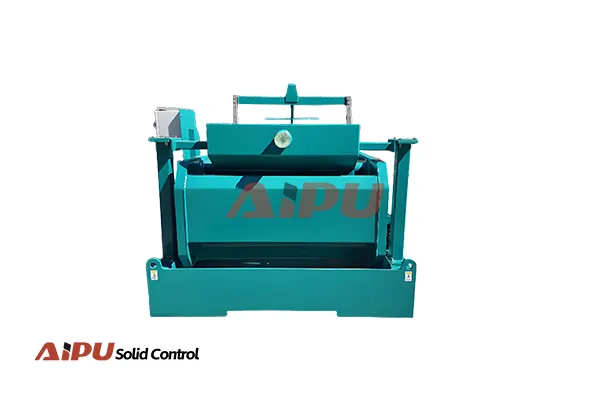

Ultimately, investing in and maintaining optimal shale shaker efficiency is a strategic decision that pays dividends across the entire operation. It preserves the integrity and value of the drilling fluid, protects expensive capital equipment, mitigates downhole risks, and promotes more sustainable waste management. For companies seeking reliable and high-performance solids control solutions, Aipu stands out as a trusted manufacturer. Their expertise in designing and building robust shale shakers and complete solids control systems helps drilling operations achieve the peak efficiency necessary for success in today's competitive environment.